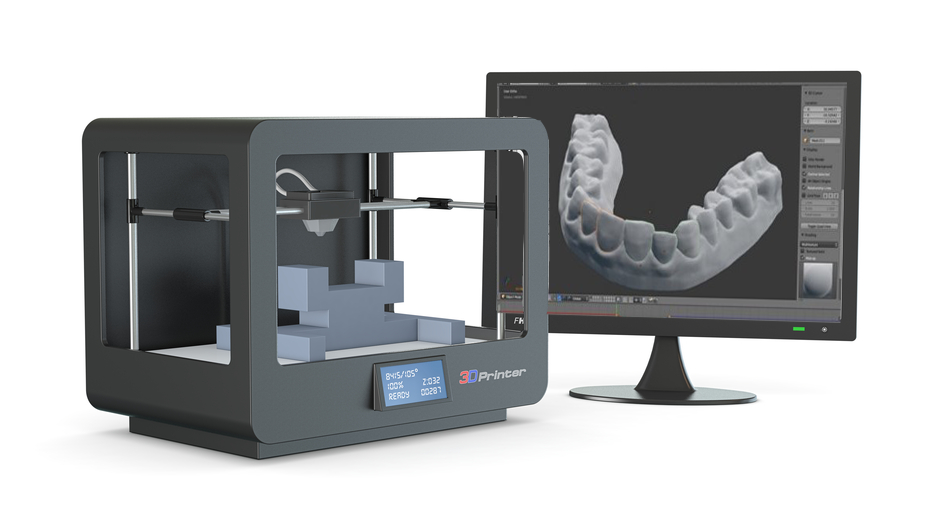

In the last two decades, three-dimensional printing made big strides towards widespread commercial and recreational availability. Now some dental organizations are catching on.

Also known as additive manufacturing, three-dimensional printing uses thin layers of material stacked on top of one another to create a physical object, guided by a digital model derived from a scan.

In dentistry, this technology has been used to replace dental molds.

A better fit

Traditional molds via a direct impression have long been thought of as the most accurate method to create plastic retainers, braces, and mouth guards.

But molds have drawbacks. If a patient gags while the mold is drying, ripples can form, and the resulting device may not fit perfectly.

Three-dimensional printers use digital scans to create the model data, eliminating the potential for ripples and improving patient comfort. Given the greater accuracy, devices created by three-dimensional printers are likely to result in a better fit real estate.

Less wasted time and space

Traditional impressions for top and bottom teeth can only be done one at a time, and must set before they are removed from the mouth, a process that can take up to twenty minutes in some cases. Compare that to a digital scan, which takes only a few minutes.

What’s more, physical molds take up space when stored for several years after the device was made (a practice followed by many dental offices). Digital impressions, on the other hand, are stored in the cloud, and don’t take up any room in a storage closet.

The wave of the future, or just a fad?

Despite the benefits listed above, three-dimensional printers certainly haven’t replaced traditional molds in dentistry just yet.

One barrier to adoption may be the cost of the equipment, which can run in the six figures for necessary printers and scanners. For Valley Orthodontic of Snohomish, Washington, the investment paid for itself in the first year. The lab prints around 200 dental devices and night guards a month.